Search This Supplers Products:CCTV security camerainfrared security camerathermal temperature cameranight vision monocularThermal imaging telescope

Application of Thermal Imaging Cameras in the Automotive Industry

time2022/05/25

- Infrared thermal imaging technology has been used in the automotive field for a long time. Below are text descriptions of some typical diagnostic applications.

Infrared thermal imaging technology has been used in the automotive field for a long time. In addition to routine thermal imaging inspections of electrical equipment in automotive production plants, the use of various infrared thermal imaging cameras in automotive development allows for more efficient, faster, and more accurate diagnosis of cars. related defects in design, structure, etc. The following are text descriptions of some typical diagnostic applications.

1. Engine fault diagnosis:

Generally, engines undergo vibration and noise testing for overall structural evaluation. However, for some small defects of the engine (such as tiny cracks, subtle structural design differences, etc.), the first two methods are difficult to diagnose accurately. Infrared thermal imaging technology can reflect subtle structural defects as subtle temperature differences, so as to achieve diagnostic results that cannot be achieved by other methods. By taking a heat map of the engine inside the car, we can see the temperature distribution inside the engine car at a glance. The temperature of each component location accurately reflects the performance of the engine in actual operation.

2. Brake system fault diagnosis:

Braking diagnostics for a vehicle depends on many factors. The front braking system is responsible for a large percentage of braking depending on weight distribution, vehicle size, and vehicle height. Using a thermal imager to compare the temperature of the front and rear wheels of a vehicle is simple and feasible.

Generally speaking, the temperature of the front wheels should be higher than the temperature of the rear wheels. If the two front wheels (or the rear) also have different temperatures, you can tell the braking system lacks smoothness, possibly due to air. The above picture shows the real temperature distribution of the front wheel.

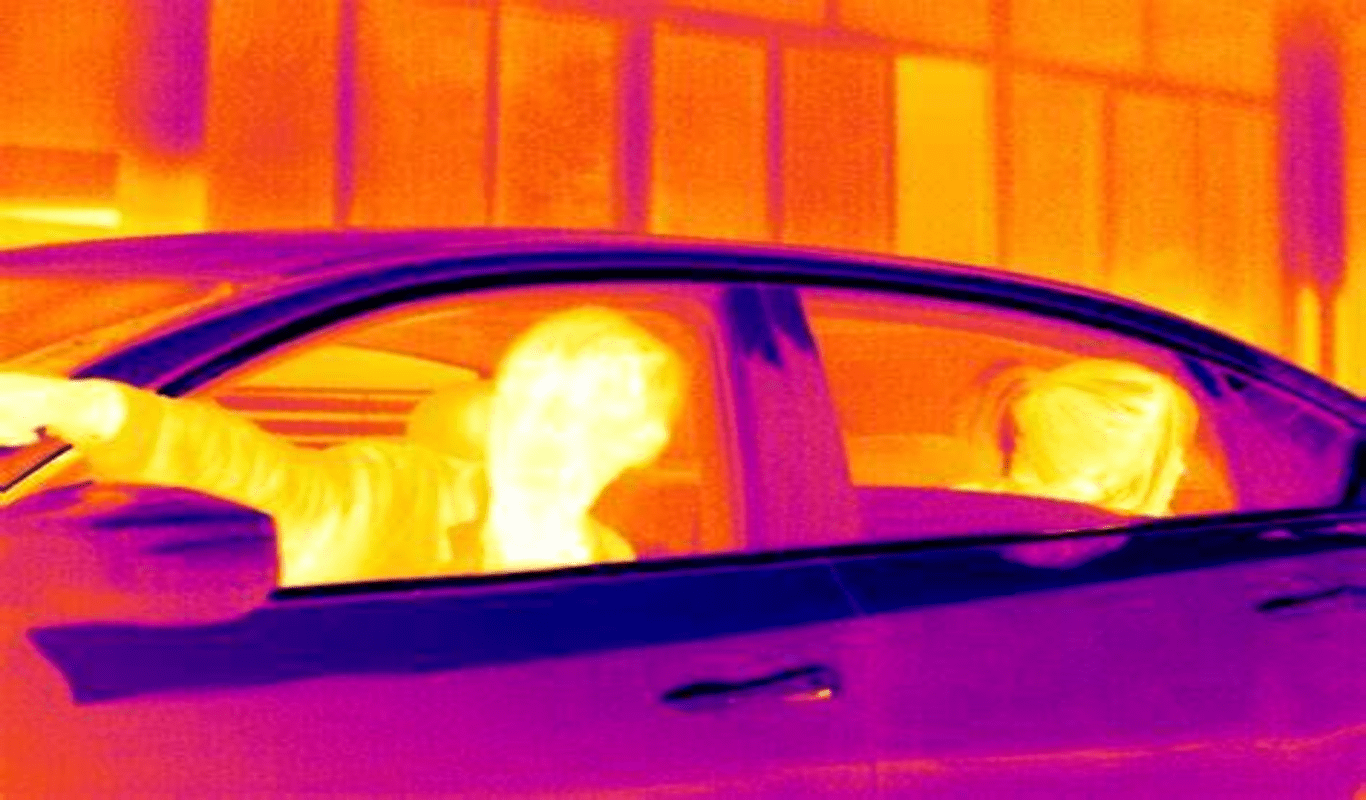

3. Body air tightness test:

The quality of the car air conditioning system is very important to the use of the car, and the overall airtightness of the body will directly affect the efficiency of the air conditioning system. When testing the car, turn on the air conditioning system in the car (run for a period of time), and then take a picture of the whole car with an infrared camera. If the airtight leak occurs in the door, glass seam, etc., it can be seen that the temperature here is different from the ambient temperature. This provides accurate analysis and evaluation of the overall airtightness of the body.

4. Detection of window heating wire:

The heating wire is located in the rear glass of the car, and its normal operation will directly affect the safe driving of the car in heavy fog. The use of thermal imaging cameras allows a comprehensive and rapid diagnosis of the distribution of the entire heating wire.

5. Detection of automobile exhaust pipe:

Excessive exhaust pipe temperature can reflect insufficient combustion, thereby indirectly assessing the operating condition of the engine system. If the temperature distribution of the pipeline is not uniform, it can reflect the structural defects of the pipeline itself. Others, the bearing system of the car chassis, electrical equipment, the comfort of the body, etc., can be detected and diagnosed by thermal imaging cameras.

6. Motor detection:

The most common motor failures are bearing damage and stator and rotor friction. The common feature of both is that in the event of a failure, the temperature inside the motor and the casing will rise significantly. Thermal imaging cameras are based on this feature.

Bearing failure:

Under normal circumstances, after running for a period of time, the bearing will gradually wear out and eventually become unusable. this is a normal phenomenon. However, the foundation of the motor is unstable, the mechanical transmission is unstable, the vibration is too large, the intrusion of dirt and impurities, too much or too little lubricating oil, and unreasonable bearing loading and unloading methods cause the bearings to be quickly damaged. The obvious signs of bearing damage are: the bearing and bearing cover is overheated, the vibration of the motor is intensified, and abnormal noise is emitted, which increases the load torque of the motor, causing the motor to overheat, and often causes the motor to rotate.

Fixed rotor failure:

The reasons for the friction between the stator and the rotor of the motor are in addition to bearing damage, bending of the rotating shaft, deformation of the iron core, cracking of the base and the end cover, and the end of the end cover is not tight. The internal friction of the motor will cause the rotor to rub. The friction between the stator and the rotor will cause strong sound and vibration of the motor, resulting in high temperature on the friction surface. In severe cases, smoke and sparks are also produced. The insulating material on the surface of the fuel tank becomes brittle at high temperatures and even burns the coils.

How to do infrared thermal image detection of motor

While acquiring infrared images, the infrared thermal imager can also directly display the highest or lowest temperature value of the subject. When the above two faults occur, the temperature of the fault part will be abnormally high. The infrared thermal imager can accurately detect the highest temperature, so as to directly find the exact location of the fault, which is fast and convenient, and can greatly reduce the time for the staff to check the fault.

7. Car tire inspection:

Tires shoulder the heavy responsibility of car safety, and their quality and performance are related to the overall performance of the car. The properties of tire materials are closely related to temperature. By observing the surface temperature of the tire, you can understand the overall working condition of the tire.

Too high a tire surface temperature can severely degrade the performance of the tire material, leading to rapid tire damage; if the temperature is too low, the grip provided is not enough to withstand the power of the car, and the car can be difficult to handle and skid.

Using a thermal imaging system to monitor and analyze the temperature of running tires can help tire design engineers test tire performance more intuitively. It can also help improve tire design, select better tire materials, improve tire product quality, and the overall performance of the car.

8. Automotive air conditioning testing:

Dust clogged

The evaporator of the automobile air conditioner is exposed to a dusty environment for a long time. If it is not cleaned in time, the fins of the heat exchanger will be too thick or dirty. If the evaporator fins or the outer filter are blocked, the indoor air volume will be insufficient and the cooling efficiency will be low. If the condenser fins are blocked, the flow resistance of the incoming and outgoing airflow will increase, the air volume will decrease, and the condensing pressure and condensing temperature will increase.

When the ambient temperature is high in summer, the compressor will start and stop frequently, and even burn the compressor and drag the motor.

An infrared thermal imager can be used to check the difference between the normal position and the vacuuming position displayed during the operation of the evaporator, so as to quickly find the dust collecting position and deal with the maintenance personnel in time.

Damage and deformation of fins

The evaporator and condenser fins (also known as fins) are tightly sleeved on the outer wall of the copper tube, and the fins are evenly spaced. For example, if the fins are accidentally knocked down during transportation and installation, the light will affect the airflow in and out, reduce the heat exchange efficiency, and reduce the cooling capacity or heat (heat pump type).

Pipe rupture and leakage

Evaporator and condenser coil or U-tube welded. When the welding head leaks, oil traces generally appear. This failure may result in low evaporating temperature and pressure or low condensing temperature and pressure.

The evaporator is monitored. If the leak is serious, it can be seen directly through the monitored infrared image. If only in doubt, you can analyze whether there is a real leak by monitoring temperature trends over time.

Evaporator frost ice

Whether it is an integrated air conditioner or a split air conditioner when the cooling is normal in summer, the condensation on the indoor evaporator is normal, but the frosting is incorrect. Evaporator frosting (icing) is generally not caused by the evaporator itself. The reasons for frosting are:

(1) The thermostat is faulty or the temperature setting is too low;

(2) The air volume is too small;

(3) The refrigerant is too much or insufficient;

(4) The pressure of the evaporator is too low;

(5) The surface of the evaporator is dirty;

The above introduces the application of thermal imaging cameras in the automotive industry. If you plan to purchase thermal imaging cameras, please contact us.

Thermeye is a professional custom thermal imaging camera manufacturer. We have a strong R&D team, professional technical engineers and a thoughtful service sales department, from product development, sample production, and functional testing to equipment packaging, we are 100% focused on providing products with high satisfaction.