Search This Supplers Products:CCTV security camerainfrared security camerathermal temperature cameranight vision monocularThermal imaging telescope

How to Use Thermal Imaging Cameras to Improve the Heat Dissipation Design Efficiency of Electronic Products?

time2021/12/14

- In this article, TermTec shared the specific methods of thermal imaging cameras to improve the efficiency of thermal design of electronic products, so that everyone can understand the characteristics and advantages of thermal imaging cameras in more detail.

Overheating has always been the enemy of the stable and reliable operation of electronic products. When thermal management R&D personnel do product demonstration and design, they need to take care of the needs of different market entities and achieve the best balance between performance indicators and overall costs.

With the flexible use of thermal imaging cameras, R&D personnel can greatly improve the work efficiency of all aspects of heat dissipation design. The following is the specific method of thermal imaging camera to improve the efficiency of thermal design of electronic products.

A quick assessment of heat load

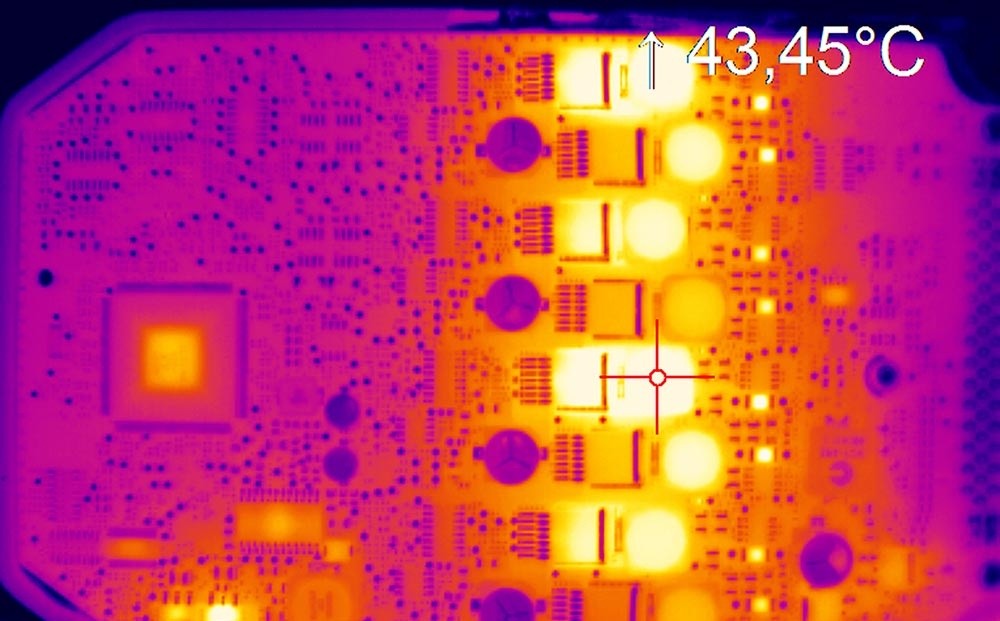

Infrared thermal imaging cameras can visually image the temperature distribution of the product, helping R&D personnel accurately assess the thermal distribution, locate areas with excessive thermal load, and make subsequent heat dissipation design more targeted.

Thermal solution evaluation and verification

There will be a variety of heat dissipation schemes in the design stage. The TermTec thermal imaging camera can help R&D personnel quickly and intuitively evaluate different heat dissipation schemes and determine the technical route.

For example, placing a discrete heat source on a large metal heat sink creates a large thermal gradient because the heat is slowly conducted through the aluminum to the fins.

The R&D personnel plan to implant heat pipes in the radiator to reduce the thickness of the radiator plate and the area of the radiator, reducing the dependence on forced convection so as to achieve noise reduction, and ensure the long-term stable operation of the product. Infrared thermal imaging cameras can be very good. To help engineers evaluate the effectiveness of the program.

Furthermore, R&D personnel needs to design the layout and contact of the heat source and heat pipe radiator. With the help of infrared thermal imaging cameras, R&D personnel found that the heat source and radiator can use heat pipes to realize the isolation and transmission of heat, which makes the design of the product more flexible.

Comparison and selection of heat dissipation materials

After determining the heat dissipation plan, R&D personnel needs to test and screen different specifications of heat dissipation materials provided by the supplier to achieve a balance between heat dissipation indicators and costs.

For example, in electronic products such as mobile phones, navigation, and smart hardware, flexible thermal conductive materials such as aluminum foil patches and graphite heat dissipation films are used for heat dissipation. These materials have different brands, processes, and specifications. With the help of infrared thermal imaging cameras, R&D personnel can quickly evaluate their heat dissipation effect, consider the performance index and cost to determine the appropriate material.

For another example, aluminum alloy radiators usually have high thermal conductivity, but poor heat radiation efficiency. The heat radiation performance can be improved through technologies such as ultrasonic mechanical coating and armoring, so as to improve the overall heat dissipation efficiency without increasing the volume.

Whole machine verification test

Before being put on the market, the product needs to be tested on the whole machine to verify that the heat dissipation design meets the requirements of regulations and standards, and can ensure the stable and reliable operation of the product. The verification test needs to simulate different working conditions and last a long time. Infrared thermal imaging cameras can assist engineers in completing tests during the product verification phase (for example, as shown below).

(1) Mobile phone test

(2) Laptop test

(3) LED lighting test

Infrared thermal imaging cameras make the design of electronic products more reliable and stable and greatly improve their operating efficiency. If you want to learn more about infrared thermal imaging cameras after reading the above, you can get a comprehensive solution by contacting us.

As a professional manufacturer of thermal imaging cameras, TermTec always puts the needs of customers first and strictly controls the design and quality of its products. Our products are sold all over the world and have received praise and trust from many customers. We can also provide users with thoughtful one-stop shopping services and effective solution technology. If you want to buy our thermal imaging camera, please contact us immediately!